Solaris Laser — Industrial Laser Printer Series by Sector

Solaris Laser is an optimal industrial laser printer provider for a wide range of industries: food, beverage, pharma, cosmetics, tobacco, automotive, electronics, tools, chemicals, and aerospace.

Aerospace

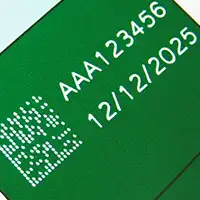

Fiber and UV industrial laser printer series are integral to the aerospace industry for marking parts with critical information, including serial numbers, part identification, and safety codes. Fiber lasers excel at marking metals, including titanium, aluminum, and steel, commonly used in aircraft structures and engine parts, providing permanent, precise marks that withstand extreme temperatures and harsh environments and are essential for traceability. UV is the ideal technology for marking delicate or sensitive components like electronic circuits, wiring, and coated surfaces, ensuring high-contrast, accurate marks without causing material damage. CO2 lasers are also used for marking non-metallic materials such as plastics, composites, and certain ceramics found in various aerospace components. These industrial laser printers support stringent safety standards, traceability, and improved quality assurance in aerospace manufacturing.

Industrial laser printers are essential in the toolmaking industry for marking tools and components with important information such as serial numbers, part identification, and branding. They aid compliance with industry standards, traceability, and the quality of tools. Fiber industrial lasers excel at marking metals, including steel, aluminum, and titanium tools, withstanding harsh working conditions, ensuring long-term traceability and quality control. CO2 industrial laser printers are effective for marking non-metallic substrates, such as plastic tool handles, rubber grips, and certain composites, providing enduring product identification. DPSS, including UV, lasers are ideal for marking sensitive or coated materials, such as carbide inserts or certain tool surfaces, offering high-contrast, detailed marks without damaging the material.

Industrial laser printers play a crucial role in the vehicle manufacturing industry for marking components with essential information like serial numbers, barcodes, and part identification to ensure traceability, enhanced quality control, and compliance with industry standards. Fiber is the principal sector industrial laser, perfect for coding metal parts, including chassis, engine components, and gears, creating durable marks that withstand extreme conditions like heat and wear. CO2 technology is ideal for marking non-metallic substrates like plastics for interiors and dashboards and glass for windscreens and windows, providing permanent, high-quality codes. DPSS, including UV, and industrial lasers excel at marking delicate materials, such as coated surfaces, electronics, and wiring.

In the electronics industry, CO2, fiber, and DPSS, including UV, industrial laser printers are essential for precise and durable coding on various materials for traceability, compliance, and branding purposes. Within electronics industrial lasers, CO2 lasers are effective for marking on non-metallic surfaces like plastics, often composing the casing of electrical goods, ceramics, and glass, which is often used in electronic housings and packaging. Fiber lasers, with their high power and precision, excel at marking metals, and vital substrates across electronics, including components like circuit boards and connectors. DPSS, including UV, lasers are the best choice for delicate or heat-sensitive materials, such as PCBs and microelectronics, ensuring high-contrast, detailed coding.

Laser coding is critical to the integrity and reputation of pharmaceutical companies ensuring packaging and products contain essential data such as batch numbers, expiration dates, and regulatory information vital to enhancing safety, ensuring traceability and compliance with regulations, as well as combatting anti-counterfeiting. CO2 lasers are the choice for marking on paperboard, cartons, and some plastic materials used in pharmaceutical packaging. Fiber industrial laser printers excel at coding on metal surfaces, such as foil seals, blister packs, and metal caps, while UV industrial lasers are perfect for marking delicate or sensitive materials like plastic ampoules, glass vials, and coated surfaces.

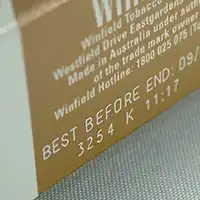

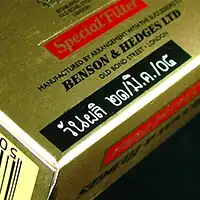

Industrial laser printers are pivotal in the tobacco industry for marking products with batch numbers, serial codes, and health warnings, helping to ensure compliance with regulatory standards and enhancing traceability. Laser coding is also very effective for reducing counterfeit risks with its difficult-to-replicate marking. By far the most popular choice of laser technology in the tobacco industry is CO2, because the technology excels on the substrates most common to the sector, paper, cardboard, and some plastics, plus it offers high speeds. DPSS, including UV, and industrial laser printers excel on sensitive materials like films or coated surfaces, while fiber lasers are commonly used for labeling metal components or foils in premium packaging.

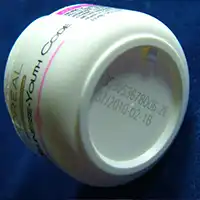

Industrial laser coding is essential in the cosmetics industry for marking products and packaging with important compliance information such as batch numbers and expiration dates. The two laser technologies principally used within cosmetics, CO2 and fiber, are also especially used in branding as they provide high-quality, more premium looking marks than other consumables-based printing technologies can produce. CO2 lasers are used to mark on paper, cardboard, and some plastics, commonly found in cosmetic packaging, like boxes and labels. Fiber industrial laser printers are perfect for coding on metal components, such as luxury cosmetic containers, caps, and foil packaging. When it comes to perfumes and markings on other cosmetics contained in glass bottles, DPSS, including UV, lasers excel at producing highly decorative designs.

The beverage industry is reliant on industrial laser printers for providing packaging with vital information such as expiration dates, batch numbers, and barcodes as well as enhancing product traceability and ensuring compliance with regulations. Industrial lasers also help ESG goals by eliminating consumable materials like ink and labels. The choice of technology comes down to the composition of the different beverage substrates: CO2 lasers are perfect for marking on glass, PET bottles, and paper labels, offering high-speed, permanent, and clear marking without the need for inks or labels. Fiber lasers are ideal for coding on metals, such as aluminum cans and foil seals, providing durable, precise markings that withstand harsh environments. UV lasers excel on sensitive materials, including thin plastics, such as HDPE and coated surfaces.

Industrial laser printers are used across the chemicals industry for marking containers, labels, and packaging with essential information, including product identification for traceability and compliance, safety warnings, and batch codes. Fiber lasers excel at coding on metal surfaces, including certain chemical drums, barrels, and metal tags, delivering precise and durable marks that can resist corrosive substances and extreme temperatures. CO2 lasers are well-suited for marking non-metallic materials such as plastic drums, cardboard boxes, and paper labels, providing permanent marks that also withstand harsh environments. DPSS, including UV, and industrial laser printers are often used for marking sensitive or coated materials like plastic containers, glass bottles, and flexible packaging.

Laser coding is vital to the food industry for marking packaging permanently with critical information, such as expiration dates, batch numbers, and barcodes, helping to ensure safety, traceability, and compliance. The ink-free nature of industrial lasers also makes them perfect for the food industry, helping to achieve ESG objectives as well as reducing ongoing costs from inks and labels. Flexible films and foils are now the most common food packaging substrates and are suitable for laser, with the optimal technology dependent on the composition. CO2 lasers are commonly used for marking on materials like paper, cardboard, and certain plastics, including polyethylene (PE), and offer high speeds. Fiber lasers are suited for marking on metal surfaces, such as cans or foil packaging, capable of withstanding varied storage conditions. UV industrial laser printers excel at coding on delicate materials like high-density flexible films, glass, coated surfaces, and directly on certain food products.